Modular Bespoke acoustic housings for generator sets, pumps, and other industrial machinery. Designed, manufactured, and fit-out to your exact project specification.

The QSK (Quick Smart Kit) is a modular, fully customizable enclosure solution for generators and DRUPS, engineered for high-power applications up to 6 MW. Designed for critical environments, it offers seamless integration, easy installation, and low maintenance, it ensures optimal performance, compliance, and long-term reliability.

The QSK Enclosure is engineered for in-line installation, seamlessly aligning with the Genset and DRUPS production process from assembly to final product. Its modular design allows full access for testing, certification procedures, maintenance and quality checks at every stage, ensuring maximum efficiency while reducing handling times and logistics costs.

| Dimensions | Custom modular enclosures for gensets up to 6 MW, including diesel, gas, hybrid, and DRUPS systems |

| Structure | Robust and flexible solutions, with materials and configurations adaptable to any project |

| Painting and Coating | ChatGPT ha detto: High-performance finishes, with painting and anti-corrosion treatments up to C5 grade to ensure durability even in extreme environments |

| Protection | Sealing grades up to IP65, resistant to weather and dust, with additional options for enhanced safety |

| Wind resistance | Withstands up to 160 km/h wind loads |

| Fire Safety | Fire detection and suppression solutions, customized according to regulations and project requirements |

| Certifications | Compliance with major international standards, including ISO, UNI, ATEX, and other safety regulations |

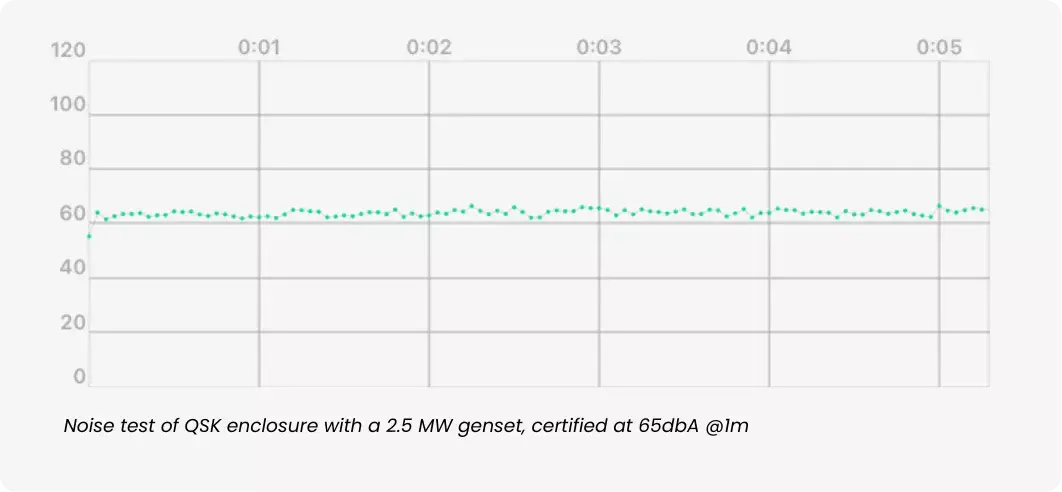

Our solutions reduce generator noise to meet even the most stringent regulatory requirements, reaching levels below 60 dB(A). Each project is custom-developed to ensure acoustic comfort and full compliance worldwide.

| Noise level | Up to 60 dBA @ 1 meter, configurable for stricter noise limits |

| Custom Acoustic Solutions | Tailored noise reduction packages available for specific project requirements |

| Ventilation Type | Natural, forced, or hybrid systems for critical environments |

| Air Intake | High-capacity louvers with optional sand traps, dust filters, and humidity control |

| Air Discharge | Aerodynamically optimized silencers for noise reduction and cooling efficiencу. |

| Cooling Compatibility | Supports radiator, heat exchanger, and remote cooling configurations |

| Standard | 15–20 m³/s | Max +10°C over ambient |

| Enhanced | 25–30 m³/s | Max +5°C over ambient |

| Extreme | oltre 35 m³/s | Custom-engineered |

| Max Temperature | Operates in ambient conditions up to 55°С, adaptable for extreme climates |

| Sealing & IP Rating | IP54-IP65, resistant to water, dust, and harsh environments |

| Extreme Conditions | Engineered for sandstorms, high humidity, and corrosive atmospheres |

| Filtration Options | Multi-stage air filtration and anticondensation systems available |

| Fire Safety | Compatible with fire suppression and emergency ventilation systems |

| Regulatory Compliance | Engineered for sandstorms, high humidity, and corrosive atmospheres |